|

CANTILEVER RACKING Composite structure,ist size and capacity can be fixed by users,it is mainly used for the storage of long figure goods such as rolled section steel,steel tube,plates and so on.

|

|

|

|

|

|

|

HEAVY TYPE BEAM RACKING Cut-in composite structure,the height of each beam is easy to adjust by pitch 75mm freely, smart section design and high-guality steel, electric reach truchs, narrow aisle turret trucks, It is the most widely used design scheme of the storage system.

|

|

DRIVE-IN RACKING It's a combination of simple Drive-in Racking and Shuttle cart, incoming the storage system, pallets to be loaded by forklifts on the shuttle cart which is located at the front end of the Drive-in system,then the shuttle cart carrying a pallet is sent to an appointed location by remote control.

|

|

|

|

|

|

|

MULTI-TIER RACKING All composite racking strcture, patented light-steel floor panel structure, locked by another patented parts which leads to an integrated smooth floor panel with high load capacity, low cost,quick construction,It can be designed into one layer or multi layers according to actual situation.

|

|

FLOW-THROUGH RACKING By using alumal or steel roller rail system and under the in fluence of gravity, "first in and first out" for the goods is implemented. It is convenient to access and suitable for places such as the two sides of the assembly line, distribution center,etc.

|

|

|

|

|

|

|

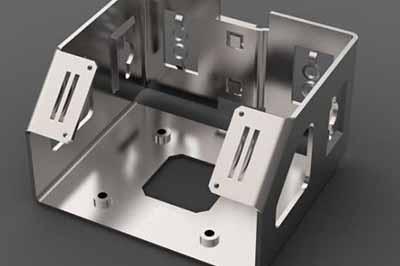

SHEET MEATL FABRICATION SERVICE Sheet metal manufacturing begins by converting CAD and drawing data into machine code. Laser cutting, water jet or plasma cutting machines then remove the sheet metal material precisely. Use brakes, punches and molds to shape raw materials into Angle bends and features. Welding, adding plug-ins or finishing parts.

|

Copyright © Chairborne Machinery Liaoning Co., Ltd. All Rights Reserved

Technical Support: