CFS Dual-Mode Sheet Metal Storage Rack: Industrial Case Study

2025-04-07 15:42

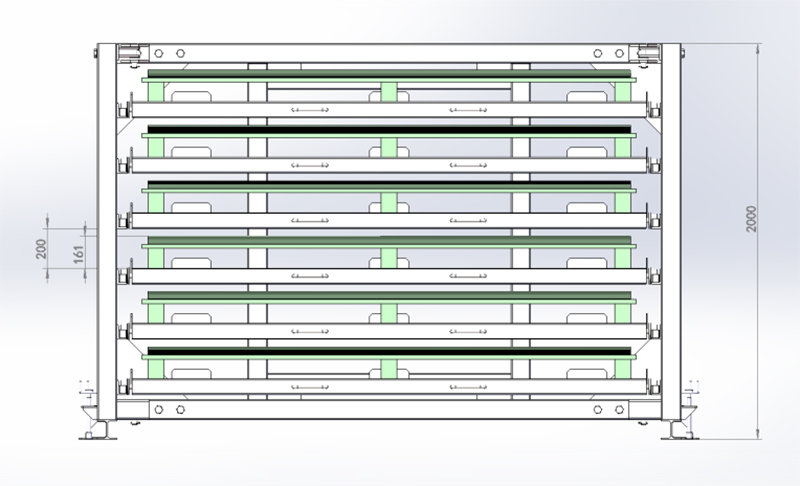

A Texas-based steel distributor required CFS sheet metal warehouse rack systems to manage mixed inventory (palletized/loose plates) with critical specifications:

●

Dual-Mode Design: Simultaneous support for 2500×1300mm pallets and 2440×1220mm loose plates4

●

Space Optimization: 2m vertical storage with 90-160mm layer spacing

●

Heavy-Duty Performance: 1,500kg/drawer capacity (1.5x safety factor)8

●

Ergonomic Handling: Vacuum lifter compatibility and crane integration

CFS Sheet Metal Storage Table Innovations

1. Adaptive Configuration Technology

Figure 1: Palletized mode (1,830kg) with 160mm clearance

●

Mode Switching:6-Drawer Pallet System: 200mm layer height for 160mm pallet+plate stacks

○

10-Drawer High-Density: 90mm spacing for 41mm loose plates4

●

Structural Engineering:Triangular gusset reinforcement at stress points

○

Dual back bracing system with seismic stability

2. Industrial-Grade Sheet Rack Storage System

Figure 2: T-track anti-derailment guides with screw-assisted braking

●

Operational Safety:Automatic drawer locks at 85% extension (OSHA-compliant)

○

Visual load capacity indicators with color-coded thresholds

●

Material Handling:40° drawer opening angle for vacuum lifter access

○

Chamfered edges prevent plate edge damage

Technical Comparison: CFS Storage Solutions

|

Parameter |

Palletized Mode |

High-Density Mode |

|

Configuration |

6 drawers |

10 drawers |

|

Total Capacity |

9 tons |

15 tons |

|

Top Handle Height |

1,673mm (5'6") |

1,803mm (5'11") |

|

Shipping Efficiency |

2 units/20'GP |

2 units/20'GP |

Operational Advantages of CFS Systems

1.

Space Optimization:Stores 35% more plates vs cantilever racks in 2m vertical space4

a.

Compatible with 5m ceiling facilities (common in retrofitted warehouses)

2.

Cost Efficiency:$12/sqm premium wooden crating option

a.

25% faster inventory turnover reduces WIP storage costs

3.

Cross-Industry Adaptability:Automotive: Body panel staging for stamping lines

a.

Construction: Steel beam organization in prefab plants

b.

Aerospace: Raw material management for CNC machining

Customization & Compliance

●

Material Specifications:5mm powder-coated steel drawers (RAL 9005 standard)

○

120×120×6mm vertical supports with seismic packages

●

Smart Logistics:RFID-enabled inventory tracking (optional upgrade)

○

3D facility modeling for layout optimization