CFS Hybrid Sheet Metal Storage Racks: Dual-Access Industrial Solution

2025-04-07 15:34

Client Requirements & CFS Engineering Approach

A Texas-based aerospace parts manufacturer sought CFS sheet metal storage solutions to manage 2440×1220mm steel plates with critical requirements:

●

Dual-Access Technology: Combine manual drawers and forklift-accessible layers

●

Precision Handling: 50mm interlayer clearance for crane-compatible workflows

●

Heavy-Duty Performance: 1,000kg/drawer capacity (1.5x safety factor)

●

Space Constraints: 1,250mm frame height for low-clearance facilities3

CFS Sheet Metal Storage Systems Innovation

1. Dual-Mode Configuration

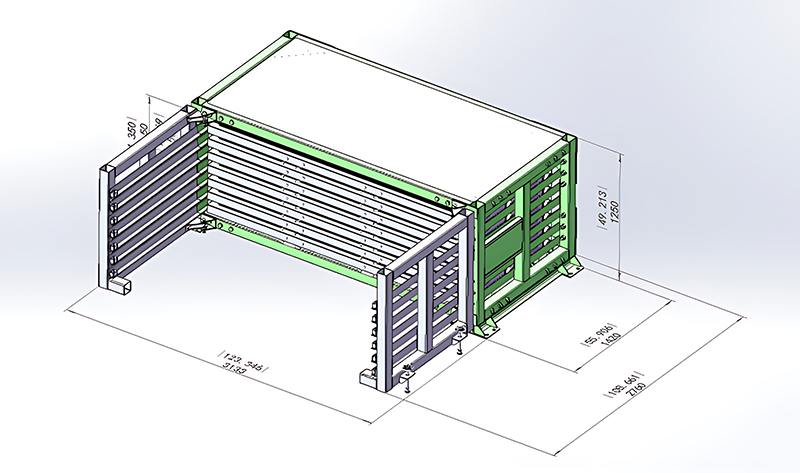

Figure 1: Hybrid system (3,100kg) with 7 manual + 4 forklift drawers

●

Flexible Workflows:Manual section: 50mm precision spacing for quality control

○

Forklift zone: T-track anti-derailment guides for 2.5-ton forklifts

●

Structural Integrity:Triangular gusset reinforcement at stress points

○

Dual back bracing for seismic stability

2. Crane-Compatible Design

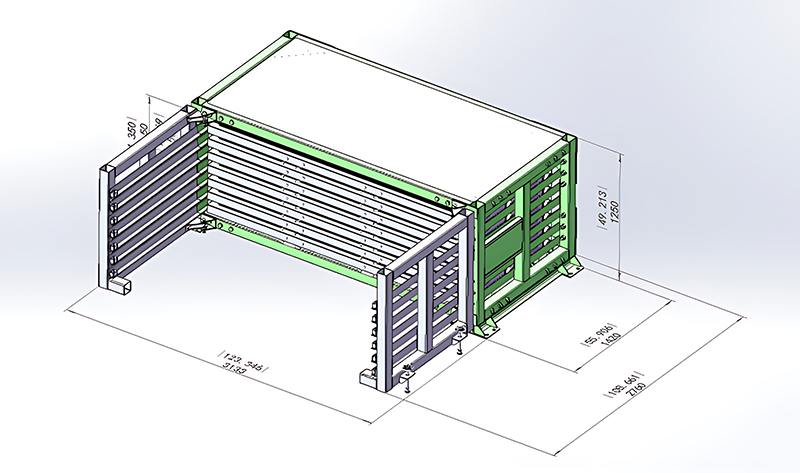

Figure 2: 1,200-1,560mm operating range for overhead lifting

●

Ergonomic Optimization:1,126mm top plate height aligns with ASME B30 crane standards

○

Chamfered edges prevent cable/chain damage

●

Safety Features:Visual load capacity indicators

○

Automatic drawer locks at 85% extension

3. Modular Sheet Metal Storage Racks

Figure 3: Bolt-together components with pre-drilled alignment

●

Field Assembly:40% faster installation vs welded systems

○

Standard tool compatibility (no specialty equipment)

●

Material Specifications:5mm powder-coated steel drawers

○

120×120×6mm vertical supports

Technical Comparison: CFS Storage Solutions

|

Parameter |

Manual System |

Hybrid System |

|

Configuration |

7 drawers |

7+4 dual-access |

|

Total Capacity |

10.5 tons |

16.5 tons |

|

Shipping Efficiency |

2 units/20'GP |

3 units/40'HQ |

|

Safety Certification |

ANSI MH31.2-2025 |

OSHA 1910.176 |

Operational Advantages of CFS Systems

1.

Space Optimization:Stores 40% more plates vs cantilever racks in 1,250mm height

a.

Fits 5m ceiling facilities (common in retrofitted warehouses)

2.

Cost Efficiency:$12/sqm premium crating option (climate-controlled)

a.

30% faster material turnover reduces WIP inventory

3.

Cross-Industry Adaptability:Aerospace: Raw material staging for wing spar production

a.

Automotive: Body panel storage for stamping lines

b.

Construction: Steel beam organization in prefab plants

Customization & Compliance

●

Regional Adaptations:Seismic zone reinforcement packages (UBC 1997 compliant)

○

Coastal corrosion-resistant coatings (ASTM B117 certified)

●

Smart Logistics:RFID-enabled drawer tracking (optional upgrade)

○

3D facility modeling for layout optimization