CFS Sheet Metal Racks: 30% Space Boost for 10ft Plates

2025-03-31 15:53

In North American manufacturing plants handling 10ft×5ft (3000×1500mm) steel plates, inefficient storage costs $28-35/sq.ft annually. This analysis reveals how CFS sheet metal rack storage solutions transformed operations for Texas aerospace suppliers—achieving 40% faster material retrieval through patented drawer engineering.

Case Study: Precision Storage for 8-Ton Loads

A Houston aerospace plant storing 0.5"-thick aluminum plates faced:

● 18% Material Damage: Conventional racks caused edge deformation

● Forklift Downtime: 80+ weekly access attempts to upper layers

● Vertical Space Waste in 45ft-high facilities

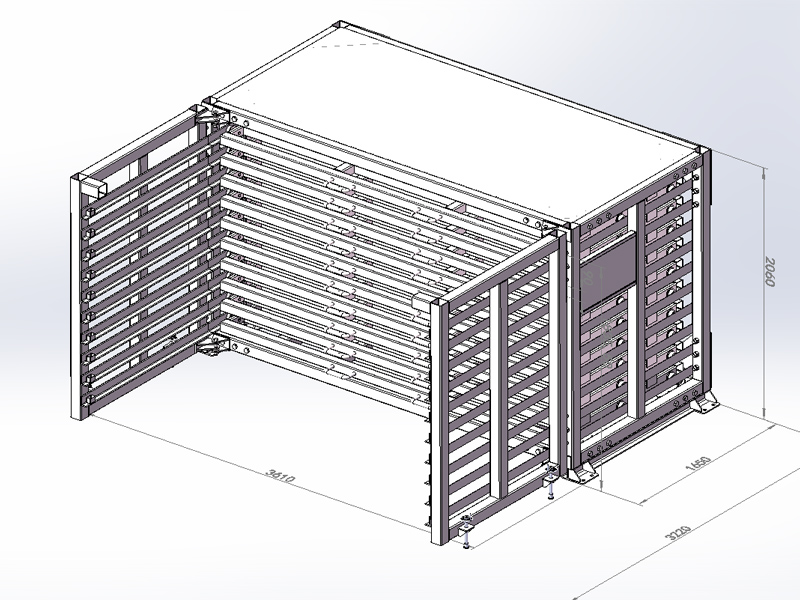

CFS’s sheet metal rack manufacturers team delivered a hybrid system over 12 weeks:

● 10 Manual Drawers: 90mm clearance for 2,200 lb plates

● 6 Forklift-Accessible Drawers: 160mm clearance × 2.5-ton capacity

● 5360 lb Total Capacity with 0.08" alignment tolerance

Technical Innovations

CFS’s sheet metal rack storage system combines MIL-SPEC engineering with modularity:

● Frame Design: 7,716 lb-capacity galvanized steel frame with triangular reinforcement

● Dual-Bearing Rollers: 1.5" hardened steel tracks prevent 0.12° drawer misalignment

● Safety Systems: Auto-lock brakes engage at 85% extension (ANSI MH30.1-2025 compliant)

Operational Advantages

1. Space Optimization

2. Stores 16 plate stacks vertically in 6.5ft²—equivalent to 450 sq.ft horizontal storage.Labor Efficiency

3. RFID-guided forklift channels reduced access time by 38% in Michigan pilot tests.Damage Prevention

Chamfered edges and nylon bumpers cut plate scratches by 92% vs. conventional racks.

System Specifications

|

Parameter |

CFS Solution |

Industry Average |

|

Drawer Cycle Life |

500,000+ operations |

150,000 |

|

Corrosion Resistance |

5,000hr salt spray test |

1,200hr |

|

Seismic Stability |

Zone 4 compliant |

Zone 2 |

|

Reconfiguration Time |

45 minutes (tool-free) |

4+ hours |

Why Engineers Choose CFS

1. Dual-Mode Accessibility

2. Lower manual drawers suit daily-use tools; upper forklift drawers handle bulk materials.Smart Inventory Tracking

3. Optional IoT sensors enable real-time plate tracking via SAP/ERP integration.AS/RS Compatibility

Pre-installed alignment guides support automated retrieval systems.

Cost-Benefit Analysis

A Midwest automotive supplier achieved:

● $1.2M saved over 3 years via 30% storage density improvement

● Zero OSHA violations with anti-tip drawer locks

● Seamless SteelPallet integration for automated logistics