In modern industrial warehouses, seamless forklift integration with storage systems is critical for operational efficiency. This case study explores how post pallet stacking racks engineered by Derack eliminate workflow bottlenecks while enhancing safety—proven through implementations in North American manufacturing hubs.

Traditional storage systems for 20-foot pipes often hinder forklift operations due to narrow access points and unstable stacking. A Midwest steel distributor reported 30% longer retrieval times and 18% higher accident rates using conventional racks. These inefficiencies highlight the need for portable stacking pallet racks designed for dynamic material handling

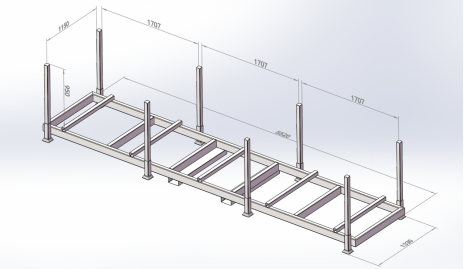

Derack’s post pallet stacking racks combine military-grade steel construction with accessibility-focused design:

Optional lockable casters enable portable stacking pallet racks to adapt to shifting production zones—ideal for just-in-time manufacturing workflows.

A Michigan auto parts manufacturer transitioned to Derack’s post pallet stacking racks for 20-foot aluminum conduits, achieving:

The system’s SteelPallet compatibility enabled direct integration with automated guided vehicles (AGVs), cutting inventory processing time by 33%

Derack’s post pallet stacking racks adhere to SteelPallet ISO 18613 benchmarks for:

Copyright © Chairborne Machinery Liaoning Co., Ltd. All Rights Reserved

Technical Support: