In today’s competitive industrial landscape, optimizing warehouse vertical space is critical for operational agility. This case study explores how heavy-duty stack racks revolutionize storage for 20-foot plastic and steel pipes, enabling businesses to maximize vertical potential while improving workflow efficiency.

Storing lengthy items like pipes traditionally requires sprawling floor space, underutilized vertical zones, and inefficient access. Disorganized layouts increase handling costs and material damage risks. Companies need robust solutions to transform stagnant storage areas into dynamic, space-efficient systems

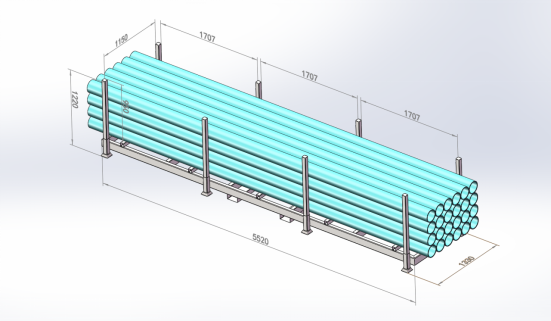

The Derack system addresses these challenges through its heavy-duty stack racks engineered for triple-tier stacking. Each unit (45" W × 37" D) provides secure containment while tripling storage capacity within the same footprint—eliminating costly facility expansions. Its open-frame design integrates seamlessly with forklifts, ensuring rapid retrieval and streamlined workflows

Hot-dip galvanized steel frames resist corrosion in harsh environments, while modular components enable easy reconfiguration. This adaptability supports evolving storage needs without requiring system replacements

A Midwest piping supplier implemented Derack’s heavy-duty stack racks to store 20-foot steel conduits. By transitioning from flat storage to vertical stacking, they achieved:

The system’s metal post pallet compatibility also simplified integration with existing logistics workflows, reducing training time by 50%

Derack’s industrial stacking racks are engineered to complement SteelPallet standards, ensuring seamless interoperability with automated material handling systems. This synergy enhances inventory tracking accuracy and reduces transition costs for facilities upgrading from traditional pallet racks

Copyright © Chairborne Machinery Liaoning Co., Ltd. All Rights Reserved

Technical Support: