How Mybox’s ISO 9001 Pallet Cages Achieved Zero-Defect Manufacturing

2025-03-25 15:24

Meta Description: Discover how Mybox’s ISO 9001-certified pallet cage systems eliminated defects for a global manufacturer. Download a free quality checklist and compliance strategies.

The Challenge: Costly Defects in High-Stakes Production

A Fortune 500 industrial equipment manufacturer faced critical quality failures:

-

8% Defect Rate: Shipped containers failed durability tests, costing $1.2M/year in recalls.

-

Supply Chain Gaps: Inconsistent part quality across suppliers risked ISO 9001 compliance.

-

EU Contract Threats: Failed audits jeopardized automotive client partnerships.

The client demanded a zero-defect solution for pallet cage production aligned with ISO 9001 standards.

The Solution: Mybox’s ISO 9001-Certified Quality Framework

Mybox deployed a four-pillar strategy to eliminate defects:

-

Process Standardization

-

Documented Workflows: Compliance with ISO 9001:2015 clause 8.5.1 for controlled production.

-

Supplier Audits: SGS-tested steel and coatings ensured raw material consistency.

-

Real-Time Quality Control

-

AI-Powered Inspections: Cameras detected 99.7% of weld flaws; laser scanners verified ±1mm tolerances.

-

QR Traceability: Each pallet cage with gate included a code linking to full production history.

-

Employee Accountability

-

ISO 9001 Training: Staff certified as internal auditors.

-

Poka-Yoke Fixtures: Error-proofed hinge and latch assembly.

-

Continuous Improvement

-

Monthly Kaizen Reviews: Reduced high-risk welding failures by 90%.

-

Client Feedback Loops: Reinforced base plates added per end-user input.

Results: Zero Defects & 40% Lower Costs

After 18 months of ISO 9001 implementation:

-

Quality Wins: 0 defects in 12,000+ shipped pallet cages; 100% pass rate in TÜV load tests.

-

Cost Savings: $480K/year saved on rework; 25% faster production cycles.

-

Compliance: Achieved EN 13698-1 standards for EU automotive contracts.

Engineering ISO 9001-Compliant Pallet Cages

-

Material Traceability

-

Batch-tracked steel with 20μm ±2μm galvanized coatings.

-

Risk Mitigation

-

FMEA analysis prioritized welding and assembly improvements.

-

User-Centric Design

-

Pallet cage with gate prototypes validated client-side for ergonomic access.

-

Multilingual manuals included stacking guidelines and load limits.

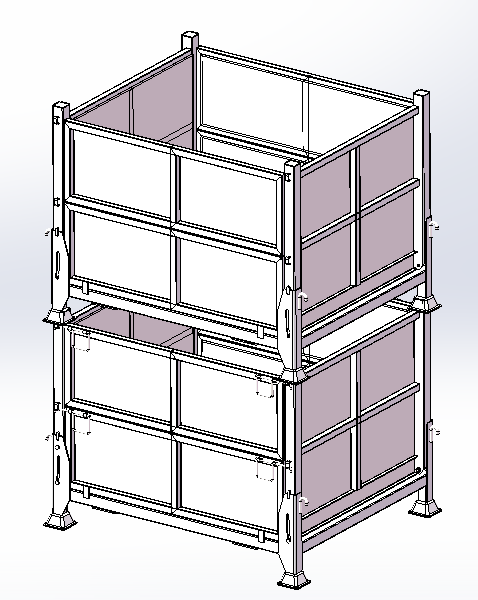

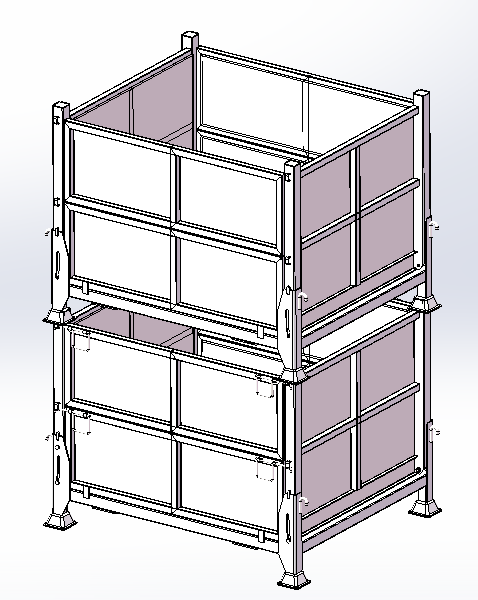

Caption: Mybox’s AI weld inspection ensures ISO 9001 compliance for pallet cage production.

Client’s Playbook: Sustaining Zero-Defect Output

-

Daily Audits: 5% random batch inspections.

-

Root Cause Analysis: 8D reports for every non-conformity.

-

Digital Dashboards: Real-time defect tracking across facilities.

[Download Free ISO 9001 Quality Checklist]

Why ISO 9001 Matters Across Pallet Cage Industries

Mybox’s framework solves universal challenges:

-

Logistics: Durable pallet cages withstand 3-layer stacking and transatlantic shipping.

-

Automotive: Secure parts storage with traceable, audit-ready systems.

-

Retail: Streamline high-volume fulfillment using standardized pallet cage with gate

Clients report 30% faster compliance with evolving regulations like REACH and RoHS.