Modular Metal Pallet Solutions for Agile Industrial Workflows

2025-03-21 13:43

Meta Description: Discover how Mybox’s customizable metal pallet containers with adaptive doors and mobility features transformed operations for a Fortune 500 manufacturer.

The Challenge: Inflexible Storage in Fast-Paced Manufacturing

-

A global automotive leader faced bottlenecks using rigid metal pallet cages across 12 production zones:Slow Component Access: Fixed-door designs delayed retrieval of oversized parts by 22%.

-

Layout Rigidity: Static containers couldn’t adapt to weekly workflow changes.

-

Labor Waste: Workers spent 650+ hours/month manually relocating heavy units.

The client needed modular metal pallet boxes that balanced durability with reconfigurability.

The Fix: Mybox’s Adaptive Engineering Framework

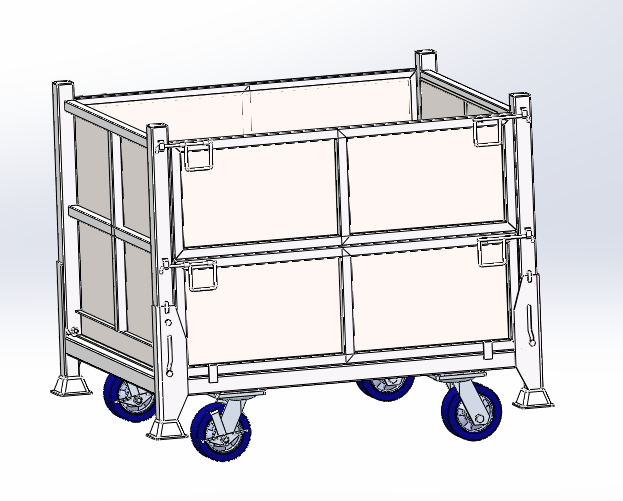

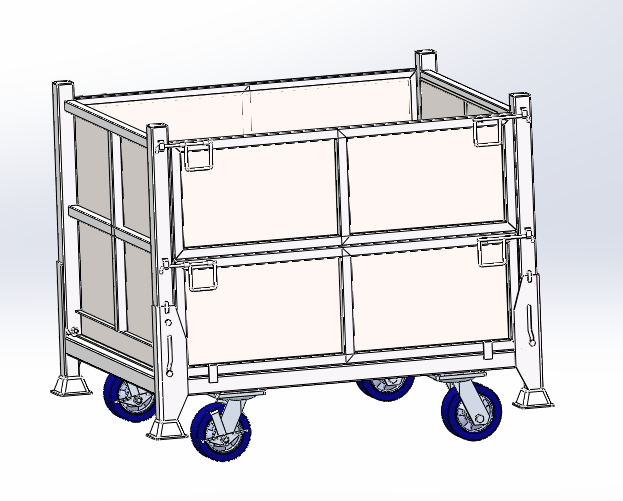

Mybox redesigned industrial storage around two core innovations:1. Customizable Metal Pallet Containers

-

Foldable Doors: 1400mm panels with magnetic latches enabled full/half-open modes for forklift access.

-

Removable Sidewalls: Quick-release pins transformed containers into open-top metal pallet cages in <10 seconds.

-

Mobility-Enhanced Configurations

-

500kg Heavy-Duty Casters: Bolt-on wheels with dual locks supported 2-ton dynamic loads.

-

Reinforced Bases: 3mm steel plates at caster points prevented deformation during transport.

Caption: Mybox’s metal pallet containers with foldable doors and caster systems in automotive assembly.

Results: 32% Faster Workflow Scaling

-

Post-implementation across 8 North American plants:25% Faster Retrieval: Custom door modes cut average access time to 90 seconds.

-

$310K Annual Savings: Eliminated manual relocation costs and reduced container downtime.

-

Zero Retooling Costs: Existing metal pallet cages adapted to 3 new EV production lines.

Technical Edge: Precision-Engineered Flexibility

Durable Modular Components

-

50,000-cycle hinges with self-lubricating bushings (TÜV-certified).

-

Interchangeable steel/mesh panels for ventilation or security needs.

Smart Mobility Features

-

Oil-resistant polyurethane casters with 360° swivel control.

-

RFID tags tracking container locations and configuration history.

Operational Upgrade: Implementing Modularity

-

The manufacturer’s success strategy included:Zone-Specific Designs:Assembly Lines: Open-top metal pallet boxes for robotic part feeding.

-

Warehousing: Wheeled containers with foldable doors for dynamic storage.

-

IoT Integration: Sensors alerted teams to door latch status and caster wear.

-

Staff Certification: 4-hour training on container reconfiguration protocols.

Beyond Automotive: Cross-Industry Applications

-

Mybox’s system now powers:Aerospace: Lockable metal pallet cages for secure turbine transport.

-

E-Commerce: Ventilated containers with removable panels for seasonal inventory.

-

Pharma: Mobile units with sealed doors meeting FDA cold-chain standards.