Mybox’s Heavy-Duty Wire Mesh Containers: 400kg to 2-Ton Load Solutions

2025-03-20 15:56

Meta Description: Discover how Mybox engineered adaptive large steel mesh stillage cages with carbon steel innovation, ISO-certified safety, and real-world durability for industrial logistics.

The Challenge: Balancing Flexibility and Strength

A global automotive parts supplier struggled with storage systems that failed under variable loads—400kg lightweight components versus 2-ton machinery parts. Their existing large mesh stillage cages suffered frame deformities and weld cracks, causing:

-

Safety Hazards: Structural failures during heavy-load operations.

-

Operational Downtime: 15% monthly repair rates.

-

Compliance Gaps: Containers fell short of ISO 9001 load-testing standards.

The solution required heavy-duty wire mesh containers adaptable to diverse loads while maintaining portability and compliance.

Innovation in Design: Mybox’s Load-Adaptive Engineering

Mybox redefined industrial storage with three breakthroughs:

-

Carbon Steel Reinvention

-

Material: High-tensile Q345B carbon steel optimized strength-to-weight ratios.

-

Durability: Cold-galvanized 20μm zinc coating resisted humidity, extending lifespan by 50%.

-

Precision: Laser-cut panels ensured seamless welds, eliminating structural weak points.

-

Load-Specific Structural Engineering

-

400kg Dynamic Capacity: 3mm anti-slip base plates and cross-bracing supported frequent forklift handling.

-

2-Ton Static Stability: 50×50mm vertical corner posts distributed weight for safe stacking.

-

Modular Upgrades: Bolt-on steel plates enabled customization for heavier loads.

-

ISO-Certified Safety Protocols

-

Testing: 10,000-cycle load tests at TÜV SÜD labs exceeded ISO 9001 requirements.

-

Safety Margins: Designed to withstand 2.5x stated capacity (5 tons) for operational variances.

Results: Zero Failures, Full Compliance

After 12 months deploying Mybox’s large steel mesh stillage cages:

-

100% Operational Uptime: Zero repairs across 200 units.

-

28% Cost Reduction: Annual maintenance savings.

-

EU Certification: Achieved ISO compliance, qualifying for multinational tenders.

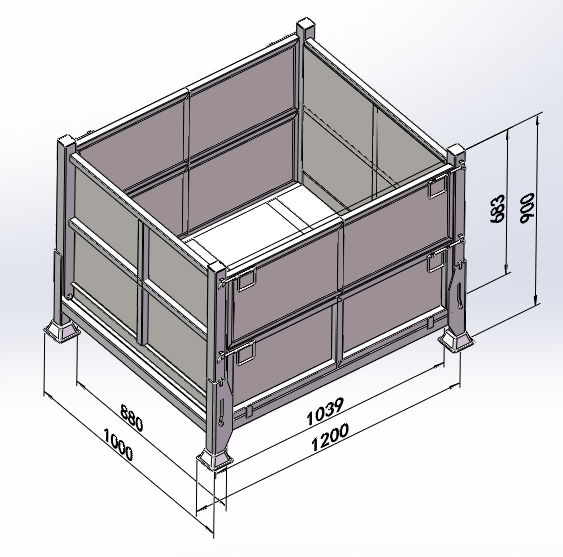

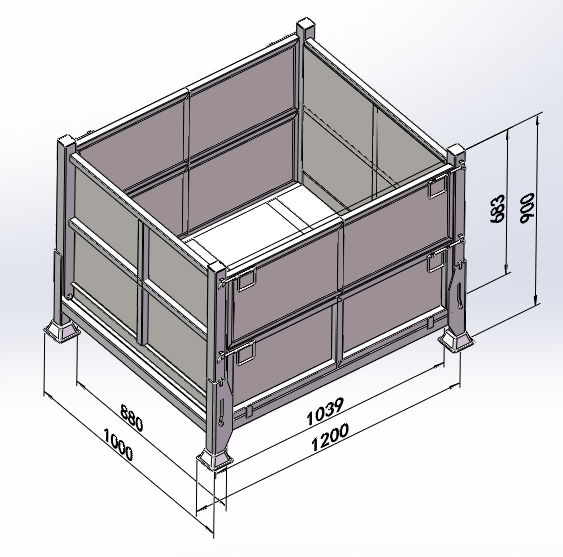

Technical Deep Dive: Engineering for Versatility

Core Components of Heavy-Duty Wire Mesh Containers:

-

Base Plate: 3mm laser-welded steel with anti-slip texture resisted 2-ton deformation.

-

Corner Posts: 50×50mm square tubes with internal gussets enabled 3-layer stacking.

-

Foldable Walls: Hinges rated for 50,000+ cycles ensured portability without compromising rigidity.

Safety Protocols:

-

Training: Certified forklift operators in load distribution best practices.

-

Monitoring: RFID tags tracked weight limits and usage history.

-

Emergency Measures: Immediate quarantine of overloaded units.

Beyond Automotive: Cross-Industry Applications

Mybox’s large mesh stillage cages set benchmarks for:

-

Manufacturing: Seamlessly store raw materials and finished goods.

-

Agriculture: Adapt from lightweight tools to heavy machinery parts.

-

Retail Logistics: Scale capacity for seasonal demand fluctuations.

ISO certification simplifies compliance for global operations, minimizing legal and insurance risks.