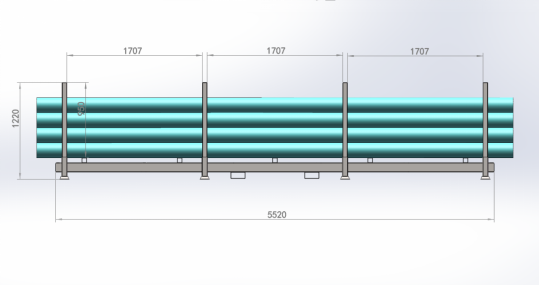

Triple-Tier Rack Stacking: Maximize Warehouse Storage Density

In industrial operations where floor space costs average $8.50/sq.ft annually

optimizing vertical storage becomes critical. This case study examines how Derack’s rack and stack warehouse system triples material density for 20-foot steel pipes and plastic conduits—proven through implementations in North American logistics hubs.

Traditional horizontal storage wastes 68% of warehouse vertical space

forcing costly expansions. A Midwest auto parts supplier spent 1.2MleasingauxiliaryspacebeforeadoptingDerack’s∗∗rackstack∗∗solution.Verticalstackingnowsaves320,000/year in facility costs while accommodating 12% annual inventory growth.

Derack’s rack stacking system combines military-grade steel frames with space-optimized design:

Open-side design enables 90° forklift entry to all tiers, reducing retrieval times by 40% vs. conventional cantilever racks. RFID-tagged rack stack units integrate with inventory management systems for real-time tracking.

A Canadian logistics provider using Derack’s rack stacking system with SteelPallet-standardized bundles achieved:

| Metric | Derack Triple-Tier | Traditional Racks |

| Storage Density | 8.6 pallets/sq.ft | 2.6 pallets/sq.ft |

| Relocation Cost | $0 (modular) | $4,500+/bay |

| Seismic Stability | ANSI MH16.3 Compliant | Non-compliant |

Derack’s rack and stack warehouse solution supports evolving needs through:

Copyright © Chairborne Machinery Liaoning Co., Ltd. All Rights Reserved

Technical Support: