Vertical Metal Plate Storage Racks for Industrial Efficiency

2025-04-15 14:31

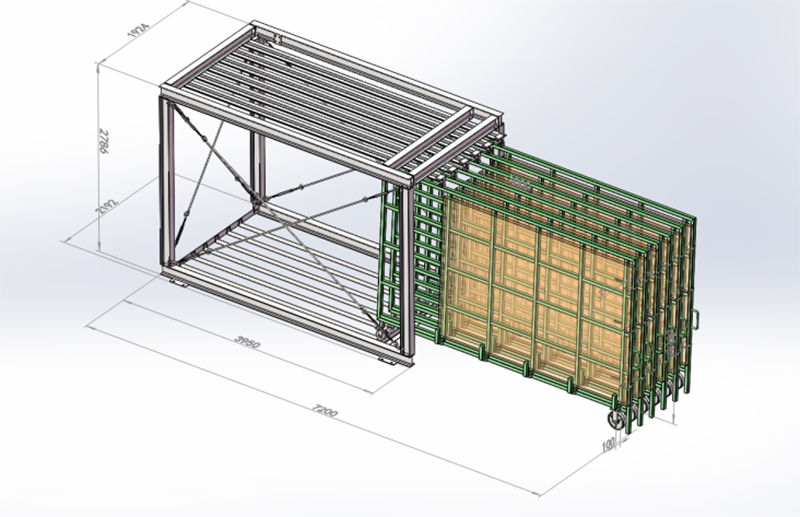

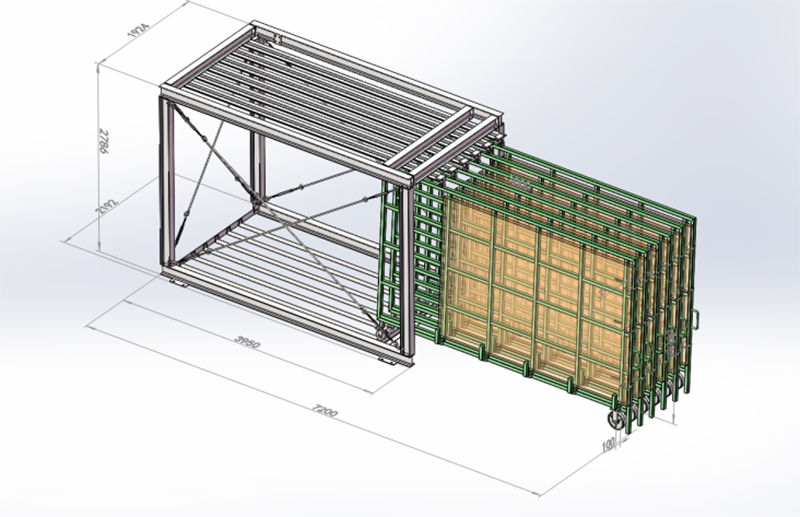

CFS redefines heavy material handling with engineered vertical metal storage racks designed for steel service centers and manufacturers requiring frequent crane access to 3,000×2,000mm plates.

Critical Operational Challenges Addressed

●

A recent client in shipbuilding required:Secure storage for 120"×78" steel plates

●

100+ daily crane access cycles

●

Choice between 1-ton and 2-ton drawer capacities

●

6-drawer vertical configuration

The CFS vertical roll-out sheet metal rack system delivered through these innovations: Precision Engineering Specifications

|

Feature |

2-Ton System |

1-Ton System |

|

Capacity/Drawer |

4,400 lbs |

2,200 lbs |

|

Drawer Extension |

283" (7200mm) |

275" (7000mm) |

|

Wheel System |

Steel V-guide |

Polyurethane dual-row |

|

Frame Construction |

1" thick steel beams |

3/4" reinforced steel |

|

Safety Tilt |

3° anti-slip |

2° secure angle |

Space-Optimized Vertical Design

●

Compact 163" (4150mm) retracted footprint

●

Vertical configuration saves 55% floor space vs horizontal racks

●

Modular design adapts to existing facility layouts

●

6-drawer system stores 72 standard plates

Crane-Ready Operation Features

●

Full 283" drawer extension for complete plate access

●

12" clearance margin for overhead crane operation

●

Durable track systems withstand 200+ daily cycles

●

Laser-aligned V-guide wheels eliminate binding

Safety-Engineered Components

●

Triple anti-tip rail system (ASTM certified)

●

Visual load capacity indicators

●

Reinforced drawer stops prevent over-extension

●

Powder-coated surfaces resist industrial wear

Global Logistics Solutions

●

Knock-down shipping fits 40ft containers

●

Protection packages:

Economy: Heavy-duty stretch wrap ($14/sqm)

●

Premium: Custom crating for overseas transport30-day assembly support with 3D installation guides

Why Manufacturers Choose CFS

1.

Workflow Optimization 50% faster plate retrieval vs traditional methods

a.

Dedicated slots prevent edge damage

2.

Scalable Configurations Expandable from 6 to 24 drawers

a.

Compatible with all major crane systems

3.

Cost Efficiency 18-month ROI through reduced handling time

a.

Low-maintenance galvanized components

Ideal Industrial Applications

●

Steel distribution centers

●

Heavy machinery manufacturing

●

Bridge component fabrication

●

Energy sector plate processing

Implementation Best Practices

1.

Anchor to 8" concrete floors using M20 bolts

2.

Maintain 6-month lubrication intervals

3.

Conduct annual structural inspections

Transform Plate Storage Workflows

●

CFS vertical metal storage racks deliver measurable operational improvements:90% reduction in plate handling accidents

●

60% faster inventory rotation

●

40% space utilization improvement

Engineered for high-cycle industrial environments, these vertical roll-out sheet metal racks combine safety with operational precision. Contact CFS storage engineers to design a customized solution matching your plate dimensions and access frequency requirements.