| Feature | Detail | Advantage |

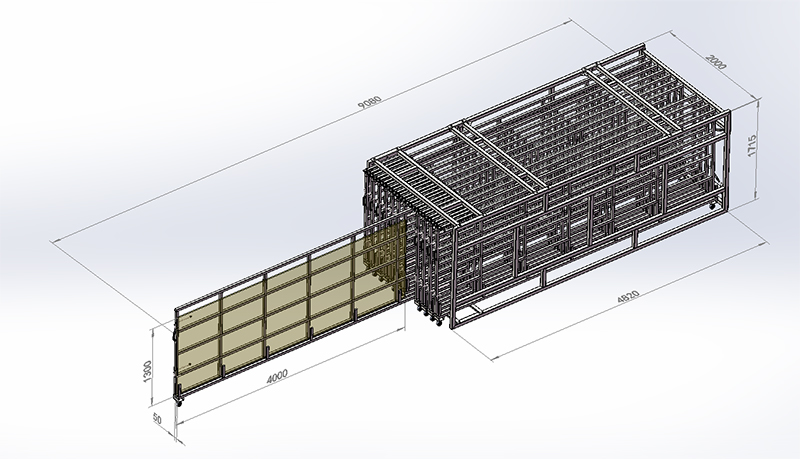

| Panel dimensions | 4,000×1,300mm capacity | Accommodates aerospace/shipbuilding materials |

| Configuration | 12 roll-out drawers | 40% space savings vs horizontal racks |

| Load capacity | 1,000kg/drawer | Supports industrial metal sheets |

| Frame design | 60×3mm steel tubing | 1,820kg structural integrity |

| Operational clearance | 10,080mm recommended | Full crane access without obstructions |

Copyright © Chairborne Machinery Liaoning Co., Ltd. All Rights Reserved

Technical Support: