A global seafood processing company faced relentless equipment degradation in their coastal facilities:

Corrosion Damage: 60% of traditional metal pallet crate solutions corroded within 18 months, requiring $220,000/year in replacements.

Temperature Challenges: Daily cycles from -10°C (cold storage) to 35°C (processing areas) warped container joints.

Regulatory Failures: Salt-laden air triggered FDA hygiene violations due to flaking rust.

The client demanded containers engineered to survive decades in aggressive environments without maintenance.

Developed with metallurgy experts, our corrosion-resistant metal pallet crate system features three innovations:

Advanced Cold-Galvanizing:

20μm Zinc Layer: Electrostatic spray ensures uniform coverage across all seams and weld points

Self-Healing Protection: Zinc sacrificially corrodes before steel, protecting scratched surfaces

1,200-Hour Salt Resistance: Exceeds ASTM B117 standards vs. 600 hours for hot-dip steel

Structural Optimization:

Q345B Carbon Steel: 345MPa yield strength balances durability and weight

Laser-Welded Joints: Eliminate moisture-trapping crevices in every metal pallet crate

Climate-Adaptive Engineering:

Thermal Expansion Joints: Rubber gaskets absorb temperature stress

Sloped Roofs: Prevent water pooling in monsoon regions

After 36 months in continuous operation:

Zero Corrosion: No rust or pitting across 500 containers (third-party verified)

Cost Reductions:

• 70% lower replacements ($66,000/year saved)

• 30% reduced cleaning from non-porous surfaces

Full Compliance: Exceeds FDA and EU 1935/2004 food-contact standards for metal pallet crate applications

Southeast Asia Coastal Deployment:

• 85% humidity + 5mg/m³ salt air

• Zero visible corrosion at 36 months vs. 12-month competitor lifespan

Accelerated Testing:

• -20°C to 50°C daily cycles

• 0.02mm/year corrosion rate vs. 0.15mm on painted steel

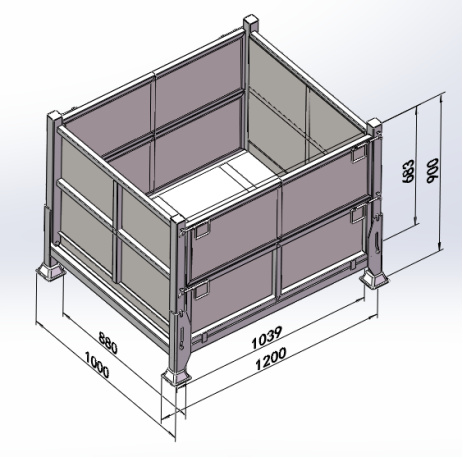

Capton: Mybox cold-galvanized metal pallet crate after 3 years in high-salinity environment

Beyond seafood processing, our solution resists:

Chemical Plants: Sulfuric acid vapors + abrasive particulates

Agriculture: Fertilizer exposure + UV degradation

Renewable Energy: Offshore wind farm salt spray

End-of-life containers maintain 95% recyclability - supporting circular economy goals.

The seafood processor's ROI analysis revealed:

• 10-year lifespan vs. 3-year industry standard

• 40% residual value from pristine condition

• 15% equipment insurance discounts

Ready to eliminate corrosion costs? [Contact Mybox] for a free site audit or download our Cold-Galvanized ROI Calculator.