Storing long materials like pipes demands a racking system that combines strength, adaptability, and space efficiency. This case study (Project No. 14593) details how we engineered a bespoke cantilever pipe rack for a client managing 3–12-meter pipes with a robust 2.5-ton capacity per level. Discover why this solution could revolutionize your warehouse operations.

The project required a system tailored to specific industrial needs:

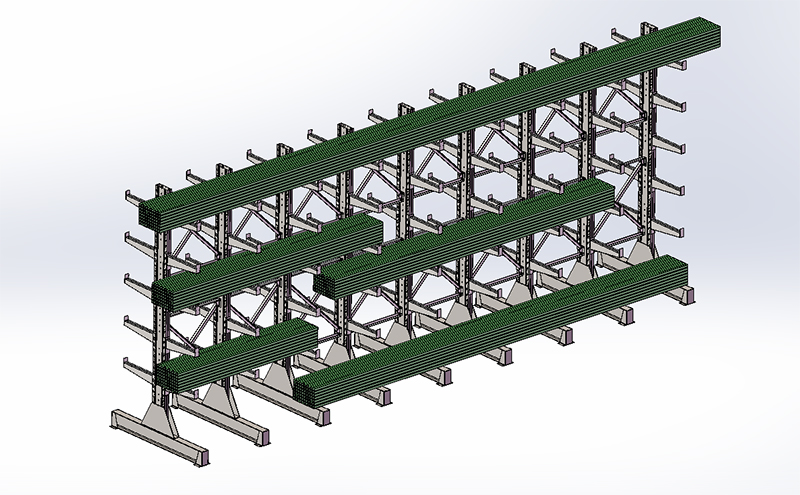

Our cantilever pipe rack design delivered unmatched versatility and durability:

Space & Accessibility

The open-front design eliminates obstructions, enabling direct forklift access and reducing handling time by 30%. Vertical space optimization allows 5 storage tiers within 4.5 meters, maximizing cubic warehouse volume.

Durability & Safety

Hot-dipped galvanized steel components resist corrosion, while anchored base columns (secured with expansion bolts) prevent tipping under maximum loads. Load stops on arms secure pipes during seismic shifts or impacts.

Operational Flexibility

Adjustable arm heights and lengths adapt to inventory changes. Single-sided configurations simplify installation against walls, while clear aisle visibility streamlines inventory checks.

Racks ship disassembled with remote assembly support. Two packaging options ensure cost-effective delivery:

Typical project milestones:

Total lead time: 6–10 weeks from order to operational readiness.

Proactive measures ensure long-term performance:

This cantilever pipe rack system demonstrates how custom engineering solves complex storage challenges. With 2.5-ton tier capacity and 12-meter span flexibility, it streamlines operations in industries like construction, metalworking, or logistics.

Ready to optimize your space? Contact our engineering team for a tailored solution.