Heavy-Duty Cantilever Lumber Rack: Transforming Long-Material Storage

2025-06-17 15:55

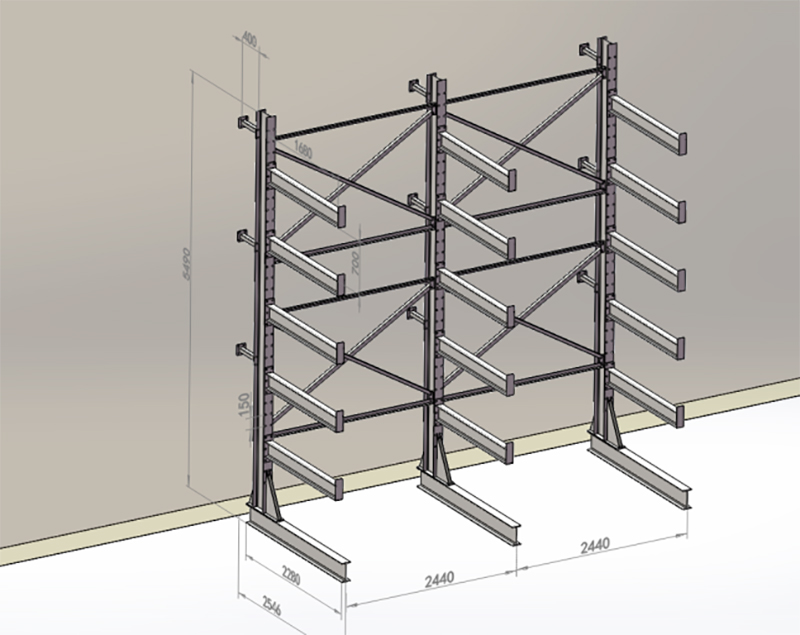

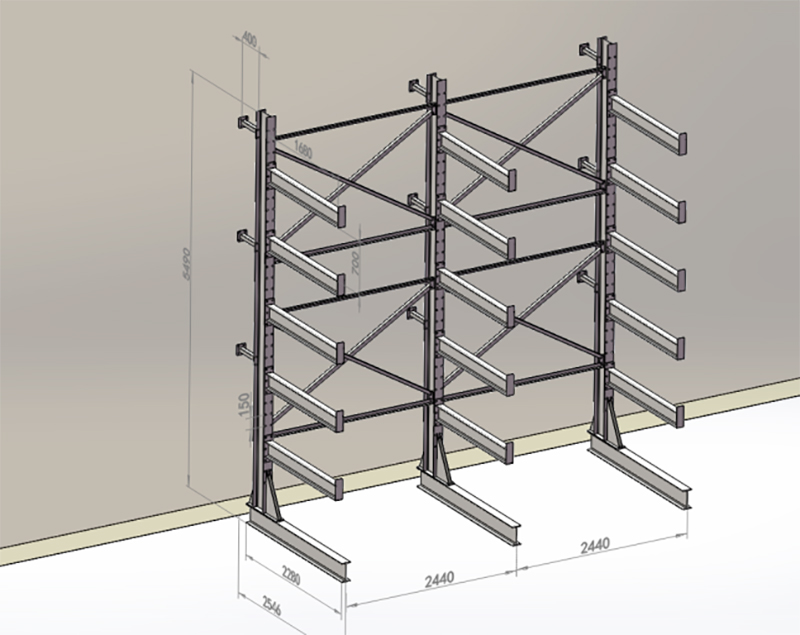

Warehouses and manufacturing facilities globally struggle to store long, bulky materials like timber and planks efficiently. This case study reveals how a custom-engineered cantilever lumber rack system solved critical storage challenges for a client requiring robust, space-optimized solutions for board storage.

Client Requirements: Precision Storage Demands

The project addressed specific operational needs:

-

Storage of 4.8m+ long boards against warehouse walls

-

2-ton capacity per storage level

-

Wall-mounted stability for seismic safety

-

Adjustable configuration for evolving inventory

Technical Implementation: Engineered for Heavy Loads

The cantilever lumber rack design delivered:

-

H-beam steel construction with 5,490mm height

-

1,680mm arms at 150mm adjustable intervals[1,6](@ref)

-

Triangular gusset reinforcements at column bases

-

5-tier configuration + base level (12 total storage planes)

Design Advantages Over Conventional Racking

Uncompromised Stability

Wall-anchored columns with auxiliary connections prevent tipping under maximum 2-ton/arm loads[1,10](@ref).

Operational Flexibility

-

150mm arm spacing adjustments accommodate diverse board thicknesses[1](@ref)

-

Single-sided configuration reclaims aisle space[6](@ref)

Heavy-Duty Performance

Hot-rolled structural steel arms withstand repeated 4,400lb loading cycles[2,6](@ref) - ideal for hardwood and engineered lumber.

Industry Applications Beyond Lumber

This cantilever lumber rack technology adapts to diverse sectors:

-

Construction: 8m rebar storage (2,200kg/arm capacity)[2](@ref)

-

Manufacturing: Steel tubing storage with non-marking arm protectors[10](@ref)

-

Retail: Oversized product displays with rapid reconfiguration[2](@ref)

Implementation Timeline

|

Phase |

Duration |

Key Milestones |

|

Design Finalization |

10 business days |

3D modeling & load simulations |

|

Manufacturing |

4 weeks |

Hot-dip galvanizing for corrosion resistance |

|

Installation |

8 days |

Laser-aligned wall anchoring |

Quantified Operational Impact

-

70% space recovery vs. floor stacking

-

3-minute retrieval vs. 15+ minutes with traditional methods[3](@ref)

-

Zero material damage in 12-month post-installation period

-

100% ROI achieved in 14 months through labor/storage savings

The strategic deployment of cantilever lumber racks converts underutilized vertical space into high-density storage assets. By combining engineered stability, ton-class capacity, and operational flexibility, warehouses achieve sustainable efficiency gains that directly impact profitability.