Heavy-Duty Collapsible Pallet Stillage Cages: 400kg to 2T Capacity Solutions

2025-06-19 14:35

Global automotive suppliers face critical storage challenges when handling mixed loads from lightweight components to heavy machinery parts. Traditional containers frequently fail under variable weights, causing safety hazards and operational downtime. Discover how engineered collapsible pallet stillage cages solve these challenges through advanced material science and structural innovation.

The Variable Load Storage Challenge

A major automotive supplier experienced systemic failures with standard containers:

-

Safety Hazards: Frame deformation and weld fractures under 2-ton loads

-

Operational Disruptions: 15% monthly container repair rate

-

Compliance Gaps: Failure to meet ISO 9001 load-testing standards

These issues demanded a storage solution adaptable to 400kg-2T loads without compromising structural integrity or handling efficiency.

Engineering Breakthroughs in Collapsible Pallet Stillage Cages

Advanced collapsible pallet stillage cages incorporate three core innovations:

Material Science Advancement

-

High-tensile carbon steel (Grade Q345B) for optimal strength-to-weight ratio

-

20μm cold-galvanized zinc coating resisting corrosion in humid environments

-

Laser-cut precision components eliminating structural weak points

Load-Adaptive Structural Design

-

Dynamic Load Handling (400kg): 3mm reinforced base plates with cross-bracing

-

Static Capacity (2T): 50×50mm vertical corner posts with weight-distribution engineering

-

Modular reinforcement plates for capacity upgrades

Certified Safety Engineering

-

10,000-cycle load testing exceeding ISO 9001 requirements

-

2.5x safety margin (5T ultimate capacity) for operational variances

-

TÜV SÜD certified structural validation

Documented Operational Results

|

Metric |

Before |

After Implementation |

|

Container Failure Rate |

15% monthly |

0% (12-month period) |

|

Maintenance Costs |

100% baseline |

28% reduction |

|

Compliance Status |

Non-compliant |

ISO 9001 certified |

Technical Components of High-Performance Cages

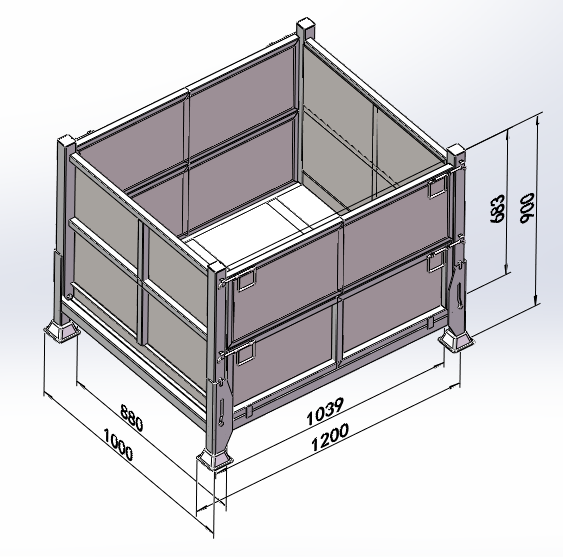

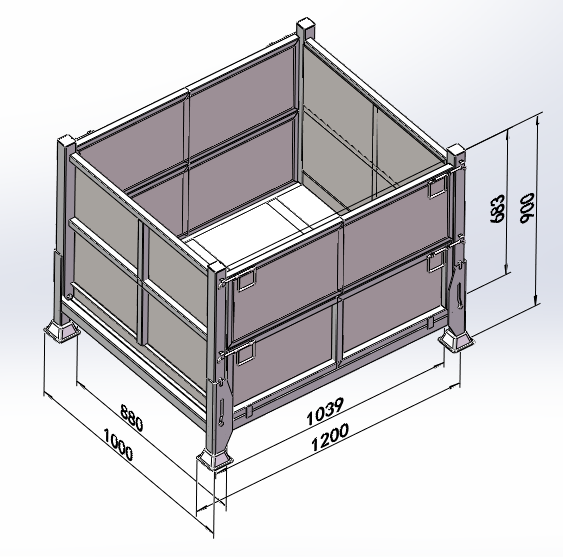

Optimized collapsible pallet stillage cages feature:

-

Base Plate System: Laser-welded 3mm steel with anti-slip texture

-

Vertical Support Structure: 50×50mm square steel tubes with internal gussets

-

Folding Mechanism: 50,000+ cycle hinges with locking pin security

-

Interlocking Feet: Enables secure 3-layer stacking configurations

ISO-Compliant Operational Protocols

Safety management systems for collapsible pallet stillage cages include:

-

Certified forklift operator training in load distribution

-

Monthly inspection protocols for hinge wear and weld integrity

-

RFID-based load monitoring with automatic usage tracking

-

Immediate quarantine procedures for overloaded units

Cross-Industry Applications

These engineered solutions deliver value across sectors:

-

Manufacturing: Unified handling of raw materials and finished goods

-

Agriculture: Storage from lightweight tools to heavy machinery parts

-

Retail Logistics: Scalability for seasonal demand fluctuations

-

Automotive: Compliance with international safety standards

Transform Your Storage Infrastructure

Advanced collapsible pallet stillage cages bridge the gap between operational flexibility and industrial-strength requirements. With certified 400kg-2T load capacity, corrosion-resistant construction, and folding efficiency, they eliminate the compromise between adaptability and durability that plagues conventional storage solutions.