Maximize Shipping Efficiency with Collapsible Stillage Systems

2025-06-19 14:55

Global logistics operations face critical challenges: 40% of container shipments transport air, wasting space and increasing costs. Discover how innovative collapsible stillage solutions enable 78% space reduction and 35% lower freight expenses while supporting sustainability goals.

The Cost of Inefficient Container Utilization

Major distributors encounter three core challenges with traditional storage solutions:

-

Space Waste: Rigid containers occupy excess volume, limiting 40HQ container utilization to 60%

-

Freight Expenses: Partial loads require additional shipments costing $4,200+ each

-

Carbon Footprint: Underutilized containers increase emissions per shipped unit

These inefficiencies directly impact profitability and sustainability metrics across global supply chains[1,8](@ref).

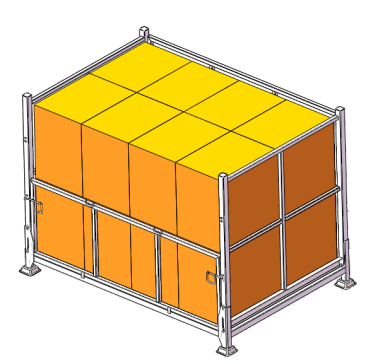

Collapsible Stillage Engineering Solutions

Advanced collapsible stillage systems solve these challenges through three patented innovations:

Space-Optimized Folding Technology

-

Vertical collapse from 1140mm to 240mm height (78% reduction)

-

Magnetic locking system enabling sub-30-second setup

-

2000×1400mm standardized footprint for seamless 40HQ stacking

Container Optimization

-

56 units per 40HQ container vs. 32 with rigid alternatives

-

75% payload capacity increase

-

147kg unit weight avoiding overweight penalties

Industrial-Grade Durability

-

1.5mm cold-galvanized steel construction

-

TÜV-certified hinges rated for 100,000+ cycles

-

Textured anti-slip flooring preventing cargo shifts

Documented Operational Results

|

Metric |

Improvement |

|

Shipping Costs |

35% reduction ($218,000 annual savings) |

|

Container Utilization |

From 60% to 95%+ |

|

Carbon Emissions |

15% reduction per shipment |

|

Loading Efficiency |

20% faster turnaround |

Implementation Protocol

Successful collapsible stillage deployment requires:

-

Workflow Integration: RFID tracking for real-time container status monitoring

-

Operator Training: Certified folding/unfolding protocols to maintain throughput

-

Vendor Partnership: On-site engineering support during initial implementation

Cross-Industry Applications

Collapsible stillage systems deliver value across sectors:

-

Retail: Eliminate peak-season shipping bottlenecks

-

Automotive: Transport bulky components without wasted space

-

Pharmaceutical: Maintain temperature-controlled payload density

-

Electronics: Protect sensitive components during transoceanic transport

Environmental and Economic Impact

Beyond operational benefits, collapsible stillage contributes to:

-

37% lower CO₂ emissions versus traditional shipping methods

-

95% recyclability at end-of-life (10+ year service life)

-

Circular economy alignment through reusable transport assets

Transform Your Logistics Operations

Advanced collapsible stillage systems represent the future of efficient shipping—merging space optimization, industrial durability, and sustainability. The proven 35% cost reduction and 78% space recovery demonstrate how intelligent storage solutions directly impact supply chain economics and environmental stewardship.