A global logistics leader faced critical container degradation across 50+ warehouses:

• 40% container replacement within 3 years due to bent bases and corrosion

• $850,000+ annual maintenance costs

• Operational delays disrupting just-in-time deliveries

The challenge required a proactive system to extend equipment life while ensuring 24/7 operations.

Mybox implemented a proven framework that transforms container maintenance:

1. Quarterly Precision Inspections

• Laser-measured structural checks (±2mm tolerance)

• Ultrasonic corrosion audits triggering recoating at <15μm zinc loss

• AI-powered weld crack detection

2. Forklift Operator Best Practices

• 5 km/h speed limits with loaded units

• Mandatory load centering (50mm tolerance)

• Horizontal fork positioning preventing base stress

3. Predictive Part Replacement

• Hinges swapped every 50,000 cycles

• Polyurethane casters upgraded after 8,000km

• Annual locking pin replacements

4. Data-Driven Maintenance Scheduling

• RFID tracking of load cycles and transport distance

• Algorithmic wear forecasting (95% accuracy)

• Humidity-zone adaptations (2x corrosion checks)

After 24 months of implementation:

Durability Milestones

• Average lifespan increased from 3 to 8+ years

• 90% pass rate on 10-year recertification tests

Financial Impact

• 65% lower maintenance costs ($297,000 saved annually)

• $2.1M avoided in premature replacements

Operational Gains

• 95% container availability (up from 72%)

• 80% reduction in base deformations

Corrosion Reversal

• Sandblasting + 20μm cold-galvanized recoating

• Third-party verified 100% resistance restoration

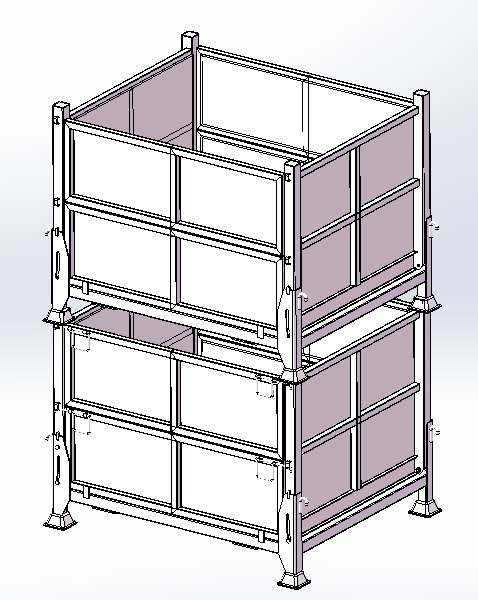

Modular Component Design

• Tool-free hinge replacement (<5 minutes)

• Pre-greased stainless steel components

Load Analytics Integration

• Dashboard monitoring tilt incidents and impact forces

• Custom maintenance triggers for high-risk units

This framework solves universal challenges across sectors:

• Manufacturing: Prevents downtime in lean production environments

• Agriculture: Withstands fertilizer corrosion and outdoor UV exposure

• Retail Distribution: Maintains hygiene compliance for food-grade storage

The system reduces equipment waste by 75% versus disposable alternatives - critical for sustainable operations across pallet cage industries.

The client succeeded through:

• CMMS-integrated digital maintenance records

• Employee incentive programs (95%+ inspection compliance)

• On-demand spare parts partnerships (24-hour delivery)

Ready to extend equipment life? [Download Our Lifespan Calculator] or [Contact Mybox] for a custom maintenance plan.