A mid-sized aerospace parts manufacturer grappled with critical productivity barriers:

• Tool Chaos: 30% of shifts wasted locating misplaced equipment

• Rigid Workstations: Fixed benches couldn't accommodate large-component assembly

• Safety Hazards: Obstructed walkways increased accident risks

The facility needed integrated solutions for storage, workflow, and safety - all within their existing 1,500m² footprint.

Mybox redefined industrial containers as adaptive workshop systems through three innovations:

1. Intelligent Tool Management

• Laser-cut dividers organized tools by type/size, cutting retrieval time 40%

• Heavy-duty castors (2-ton capacity) enabled mobile tool access

• RFID locks secured calibrated instruments within metal stillages

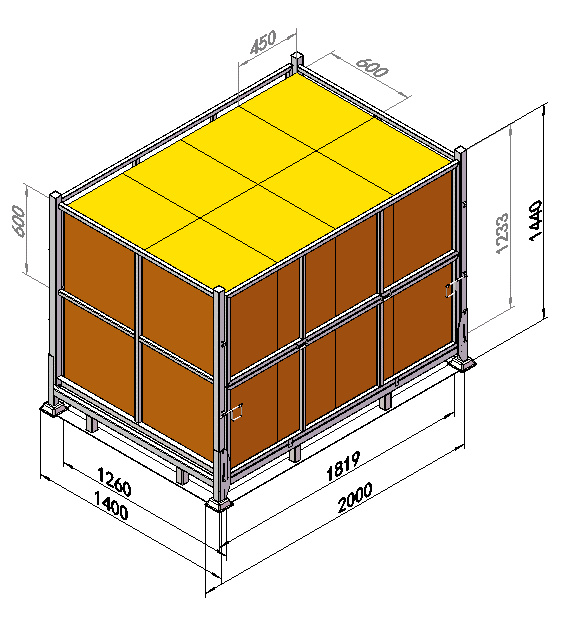

2. Instant Workstation Conversion

• 1400mm side panels unfolded into 1.2m² work surfaces (300kg load-rated)

• Integrated power strips supported industrial tools and IoT devices

• Motion-activated LED strips provided task lighting

3. Dynamic Safety Zoning

• Containers arranged as temporary fire-resistant barriers (1,200°C rated)

• Non-slip flooring met ANSI/ASSE A1264.2 standards

After 8 months:

Operational Gains

• 55% faster tool retrieval

• 25% quicker project turnover

• $150,000 saved vs. specialized equipment purchases

Safety Milestones

• Zero OSHA-recordable incidents in 12 months

• 90% fewer tripping hazards

• 20% lower energy costs via smart lighting

Tool Storage System

• Vibration-dampening foam slots in adjustable aluminum rails

• Dual-brake polyurethane wheels (oil/chemical resistant)

Workstation Integrity

• 2mm steel underplates prevented table sagging

• Auto-locking leg pins ensured stability

Safety Compliance

• Fire panels certified to FAR 25.853 aircraft standards

• IP67-rated waterproof power outlets

This system solves universal challenges:

• Automotive: Mobile stations for engine overhauls

• Construction: Weatherproof metal stillages doubling as site offices

• Hospitality: Modular kitchen carts for large venues

The approach reduced single-purpose equipment needs by 60%, supporting sustainability goals through multi-functional design.

The manufacturer succeeded by:

• Color-coded zone mapping (tools/workstations/safety)

• Employee reconfiguration training programs

• IoT sensors tracking tool utilization

Ready to transform your workspace? [Contact Mybox] for a layout audit or download our Workshop Design Guide.