A global industrial equipment manufacturer faced critical quality failures:

• 8% defect rate in shipped containers triggering $1.2M annual recalls

• Inconsistent part quality across suppliers jeopardizing production

• Failed ISO audits endangering EU automotive contracts

The client demanded true zero-defect manufacturing compliant with ISO 9001's rigorous standards.

Mybox implemented an ISO 9001-certified system:

1. Process Standardization

• Documented workflows aligned with ISO 9001:2015 Clause 8.5.1

• Third-party SGS testing for all raw materials

2. Real-Time Quality Control

• Laser scanners (±1mm tolerance checks) and AI weld inspection (99.7% detection)

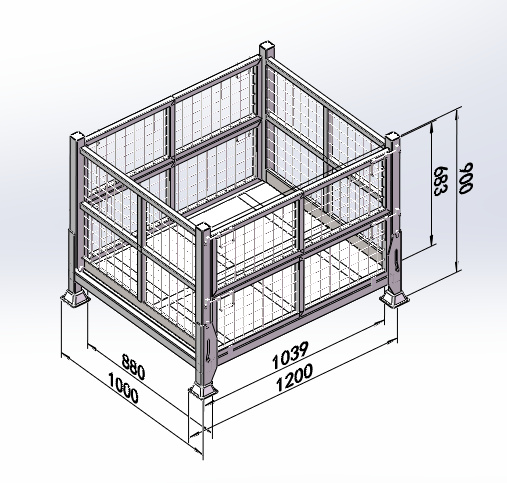

• QR traceability codes tracking every pallet cage production history

3. Employee Accountability

• ISO auditor training for all staff

• Poka-yoke fixtures preventing assembly errors

4. Continuous Improvement

• Monthly Kaizen reviews analyzing defect data

• Client-driven design enhancements

After 18 months of implementation:

Quality Milestones

• 0 defects in 12,000+ shipped units

• 100% pass rate in TÜV SÜD load tests (2.5x safety margin)

Operational Gains

• 40% lower rework costs ($480,000/year saved)

• 25% faster production cycles

Compliance Achieved

• ISO 9001:2015 certified with zero non-conformities

• Qualified for EN 13698-1 pallet standards

Material Traceability (Clause 8.5.2)

• Batch-tracked steel coils with heat-number documentation

• Hourly coating thickness measurements (20μm ±2μm)

Risk-Based Manufacturing (Clause 6.1)

• FMEA analysis reducing high-risk process failures by 90%

• Dual-sourced critical components for supply continuity

Customer-Centric Design (Clause 8.3)

• Client-validated prototype iterations for each pallet cage model

• Multilingual manuals covering load limits and maintenance

This framework addresses diverse sector challenges:

• Logistics: Ensures pallet cage durability during 3-layer stacking

• Healthcare: Material traceability for medical equipment storage

• Retail: Standardizes high-volume fulfillment processes

Clients report 30% faster compliance with emerging regulations (REACH/RoHS).

The client succeeded through:

• Daily audits of 5% production batches

• 8D root cause analysis for all non-conformities

• Real-time defect dashboards on factory floors

Ready to eliminate defects? [Contact Mybox] for a free quality assessment or download our ISO 9001 Roadmap.