Mybox Safety-Engineered Metal Cage Pallets: Zero Storage Incidents

2025-07-11 15:09

Solving Industrial Storage Failures

A global chemical manufacturer faced recurring safety incidents across five warehouses. Poorly aligned storage systems caused three major collapses in 18 months, resulting in $850k in damages and compliance gaps with ISO 9001 safety standards. Critical pain points included:

-

12% container deformation from forklift mishandling

-

Structural failures during seismic events

-

Failed safety audits risking operational licenses

The operation required metal cage pallets engineered to eliminate accidents while streamlining workflows.

Risk-Proof Engineering Framework

Mybox developed a three-pillar safety solution:

1. Collapse Prevention System

-

Patented interlocking feet with self-aligning grooves (±2mm precision)

-

8-point weight distribution reducing structural stress

-

30° tilt resistance validated in SGS lab testing

2. Forklift-Safe Reinforcement

-

3mm laser-welded steel base plates with anti-slip texture

-

Integrated guide rails minimizing handling misalignment

-

Laser-etched positioning markers for operator precision

3. Certified Safety Protocols

-

Dual-action seismic latches securing contents during impacts

-

5,000-cycle dynamic load certification (ANSI MHIA 2016)

-

Reinforced corner posts on all metal cage pallets

Documented Safety Transformation

After 12 months of deployment:

-

Zero incidents across 200+ units (no collapses/forklift damage)

-

$620k saved in incident-related losses and insurance premiums

-

18% faster loading cycles from standardized handling

-

Full ISO 9001 and ANSI MHIA 2016 certification achieved

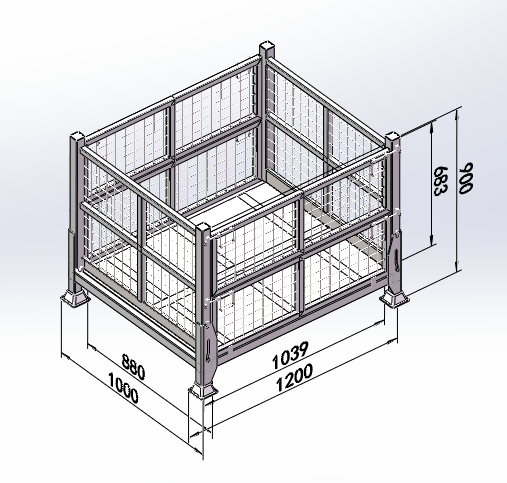

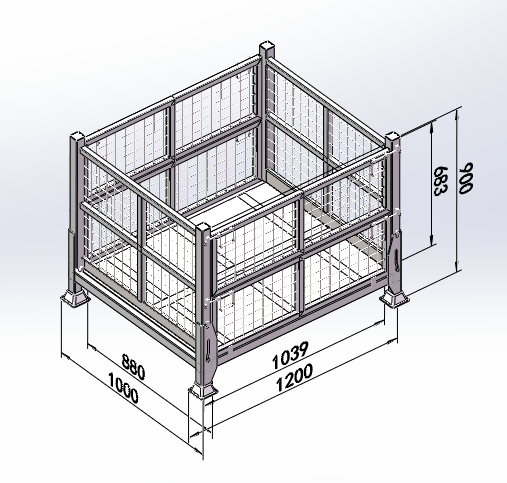

Technical Safety Innovations

Key components ensuring reliability:

-

Interlocking feet: Nylon-reinforced steel (10,000+ cycle durability)

-

Cross-braced bases: 25mm steel beams with 1.5mm impact-zone plating

-

IoT-enabled wear sensors monitoring structural integrity

-

RFID tracking for each metal cage pallet

Implementation Protocol

The manufacturer's risk mitigation strategy included:

-

Mandatory forklift operator certification

-

Monthly tilt-resistance simulation drills

-

Automated alerts for component wear

-

Digital audit logs for compliance documentation

Cross-Industry Safety Applications

This engineering approach benefits diverse sectors:

-

Retail logistics: Prevent collapses in high-velocity distribution centers

-

Automotive: Secure engine blocks during vertical stacking

-

Pharmaceuticals: Maintain FDA-compliant storage conditions

The metal cage pallets system integrates with automated guided vehicles (AGVs) and smart warehouse management platforms.

Ready to eliminate storage risks?

[Contact Mybox] for safety audit consultation