Optimize Warehouse Space with Collapsible Cage Pallet Systems

2025-06-19 14:34

A global logistics provider faced critical warehouse constraints: 95% capacity utilization and 15% annual storage cost increases. Traditional storage solutions limited vertical space efficiency and consumed excessive floor space. Discover how implementing collapsible cage pallet technology enabled 40% warehouse space recovery while enhancing operational safety.

The Warehouse Capacity Crisis

Key operational challenges demanded innovative solutions:

-

Space Utilization: Traditional rigid containers consumed 30%+ excess floor space

-

Vertical Limitations: Conventional designs restricted stacking beyond 2 layers safely

-

Transportation Inefficiency: Empty container storage compounded space constraints

-

Cost Pressures: 15% annual storage cost increases threatened profitability

These constraints necessitated a fundamental rethinking of storage methodology.

Collapsible Cage Pallet Engineering Breakthrough

The solution centered on three technical innovations:

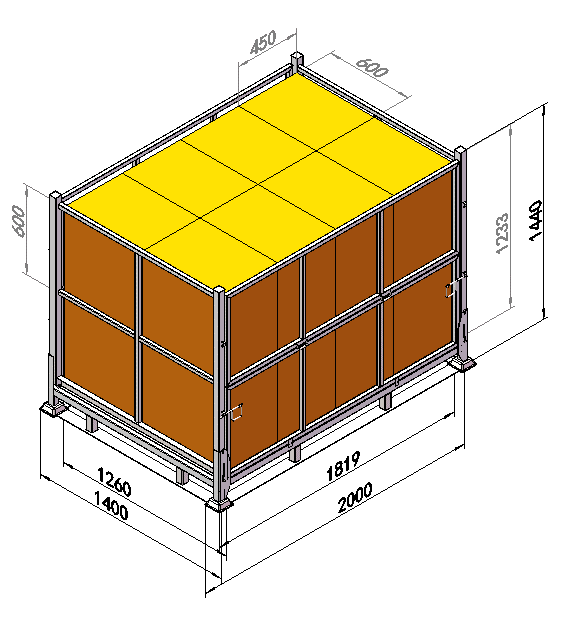

Space-Optimized Structural Design

-

Patented folding mechanism reducing storage footprint by 70% when idle

-

Precision external dimensions: 2000×1400×1140mm (standard rack compatible)

-

Interlocking foot system enabling secure 3-layer stacking

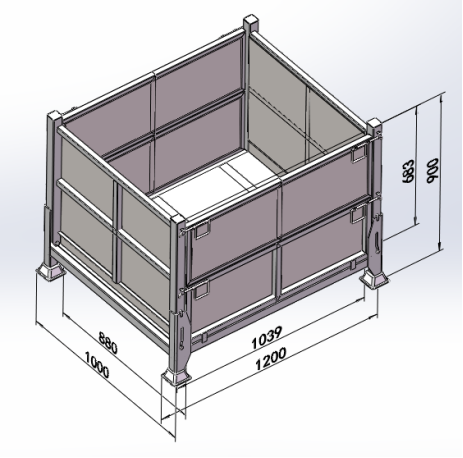

Heavy-Duty Performance Specifications

-

Cold-galvanized carbon steel construction resisting corrosion

-

Reinforced base plates supporting 12-ton cumulative stacking capacity

-

400kg dynamic / 2-ton static load rating per unit

Logistics Optimization

-

Folded profile: 2000×1400×240mm enabling 56+ units per 40HQ container

-

Standardized dimensions streamlining forklift operations

Quantifiable Operational Results

Implementation delivered transformative outcomes:

|

Metric |

Improvement |

|

Warehouse Space Utilization |

40% reduction in footprint |

|

Storage Costs |

30% reduction |

|

Loading/Unloading Efficiency |

22% faster throughput |

|

Safety Incidents |

Zero collapses (ISO 9001 certified) |

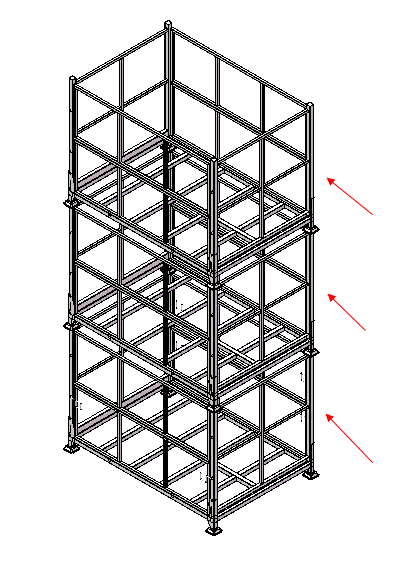

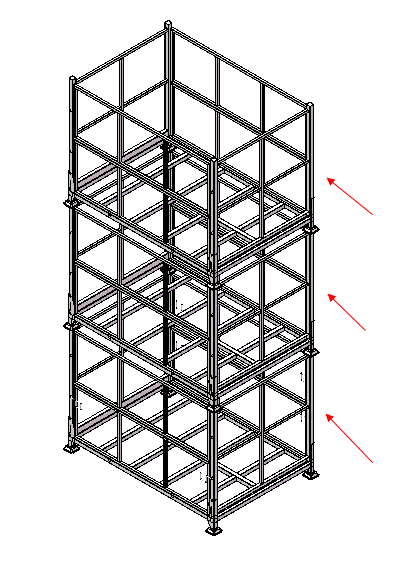

Technical Implementation: 3-Layer Stacking Protocol

The stacking methodology ensured safety and stability:

-

Base Layer: Anti-slip mat placement with precise alignment

-

Interlocking System: Patented feet creating structural continuity between layers

-

Lateral Reinforcement: Cross-bracing preventing lateral shift under load

-

Load Distribution: Reinforced corner posts transferring weight vertically

Operational Best Practices

Critical maintenance protocols from implementation:

-

Forklift Handling: 5km/h maximum speed during loaded movement

-

Preventive Inspections: Monthly checks of alignment, welds, and hinges

-

Load Management: Strict 400kg dynamic load enforcement

-

Environmental Protection: Galvanized finishes maintained in humid conditions

Strategic Business Advantages

Beyond space savings, collapsible cage pallet systems deliver:

-

Scalability: Modular design adapts to seasonal inventory fluctuations

-

Sustainability: 35% transportation reduction lowers carbon footprint

-

Competitive Throughput: Standardized dimensions accelerate workflows

-

Lifecycle Value: 5+ year service life with proper maintenance

Transform Your Storage Efficiency

Collapsible cage pallet systems represent the next evolution in warehouse optimization—merging space efficiency, structural integrity, and operational flexibility. The documented 40% space recovery and 30% cost reduction demonstrate how intelligent storage solutions directly impact profitability.