During production and encapsulation, photovoltaic (PV) panels have extremely strict requirements for surface cleanliness and scratch-free integrity. A leading North American solar energy company needed a specialized transport tool for their production line that would prevent any secondary contamination or damage from rust, flaking paint, or vibration.

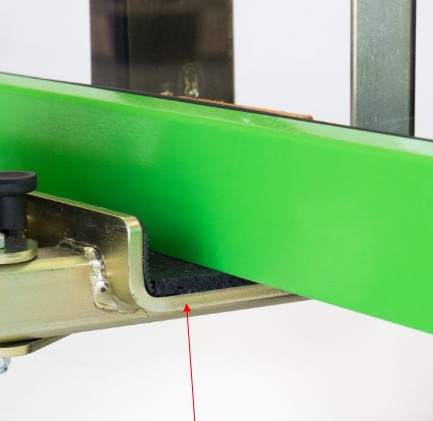

We engineered a custom slab buggy tailored to their precise needs. The entire main frame is constructed from 201 stainless steel, offering excellent corrosion resistance and completely eliminating the risk of rust contamination. For smooth transport, we equipped it with 8-inch silent, shock-absorbing swivel casters that effectively filter out vibrations from minor floor imperfections. The 4-inch wide holding channel is lined with soft rubber, providing gentle yet firm protection for the delicate panels.

We understand that for high-tech manufacturing, transport tools are an integral part of the production process and must meet the same high standards as the product itself. Through a meticulous focus on materials, shock absorption, and contact protection, our expertise in creating transport solutions ensures the perfect quality of our customers' high-value products.