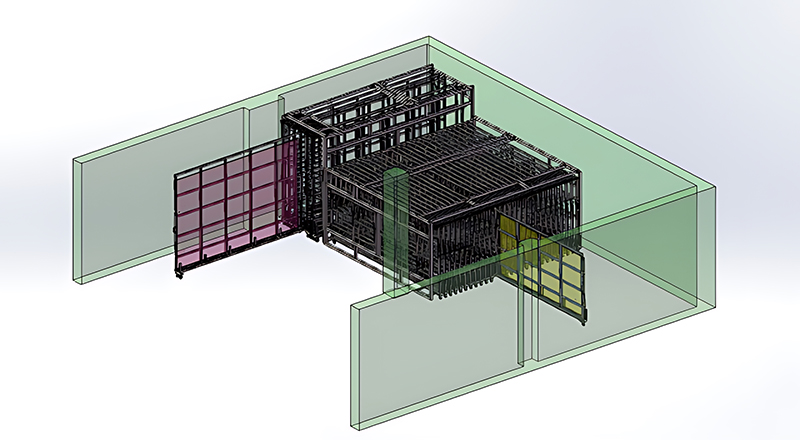

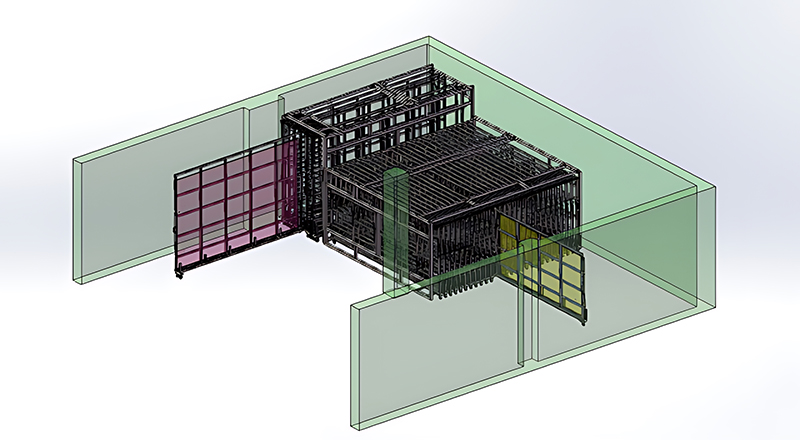

Vertical Sheet Metal Racks for Industrial Panel Storage

2025-04-15 14:43

CFS engineers vertical storage solutions that optimize space and protect sensitive materials, from acrylic sheets to metal panels. Our roll-out shelf systems adapt to diverse industrial needs while maintaining strict material safety standards.

Critical Storage Challenges Solved

●

A commercial signage manufacturer required:Dual storage for 10'×7' acrylic and 11'×7' metal sheets

●

1,100 lb capacity per shelf

●

Scratch prevention for high-value surfaces

●

Vertical configuration in existing 28'×40' warehouse

The CFS vertical sheet metal rack system delivered through these innovations: Precision Storage Specifications

|

Feature |

System 1 (Standard) |

System 2 (Heavy-Duty) |

|

Panel Capacity |

10'×5' |

11'×7' |

|

Shelf Capacity |

1,100 lbs |

1,100 lbs |

|

Vertical Clearance |

14' 4" |

16' 5" |

|

Material Spacing |

1.75" |

3.9" |

|

Frame Construction |

Powder-coated steel |

Galvanized steel |

Space-Optimized Warehouse Integration

●

Vertical sheet metal storage configuration saves 40% floor space

●

Modular design adapts to existing column layouts

●

Dual-system installation in 40ft warehouse sections

●

Clear 8' aisles for forklift access

Material Protection Engineering

●

Non-marking polyurethane rollers (200 lb/ft linear capacity)

●

Adjustable dividers prevent panel shifting

●

Scratch-resistant epoxy shelf surfaces

●

Climate-controlled spacing prevents warping

Industrial-Grade Operation Features

●

Smooth-glide roll-out shelves (70% reduction in access effort)

●

Laser-aligned tracking system (±0.12" tolerance)

●

Visual load indicators with color-coded capacity zones

●

OSHA-compliant safety stops at 85% extension

Global Logistics Solutions

●

Knock-down ships in standard 40HC containers

●

Protection packages:

Economy: Heavy-duty shrink wrap ($14/sqm)

●

Premium: Custom crating for transoceanic transport3D interactive assembly guides with AR support

Why Manufacturers Choose CFS

1.

Multi-Material Versatility Stores acrylic, wood, and sheet metal panels

a.

Quick-change shelf configurations

2.

Workflow Efficiency 65% faster material retrieval vs static racks

a.

RFID-ready inventory tracking slots

3.

Long-Term Durability 100,000-cycle shelf glide testing certification

a.

10-year corrosion warranty

Ideal Industrial Applications

●

Commercial signage production

●

Architectural metal fabricators

●

Aerospace composite storage

●

Retail display manufacturing

Implementation Best Practices

1.

Install on leveled concrete (6 PSF minimum)

2.

Maintain 18" clearance behind racks

3.

Conduct semi-annual roller bearing inspections

Transform Material Storage Operations

●

CFS vertical sheet metal racks with roll-out shelves deliver measurable ROI:80% reduction in surface damage claims

●

50% faster inventory turnover

●

35% warehouse space reallocation

Engineered for facilities prioritizing both material integrity and storage density, these systems adapt to evolving production needs. Contact CFS storage engineers to design a customized vertical solution for your panel types and workflow requirements.